EK2

Compressor of the EK line with three stages in one cylinder – particularly compact and especially suitable for installation in a small vessel.

Here you can contact us via our contact form:

Request service support or spare parts

J.P. Sauer & Sohn Maschinenbau GmbH

Brauner Berg 15

24159 Kiel / Germany

+49 431 3940-0 more

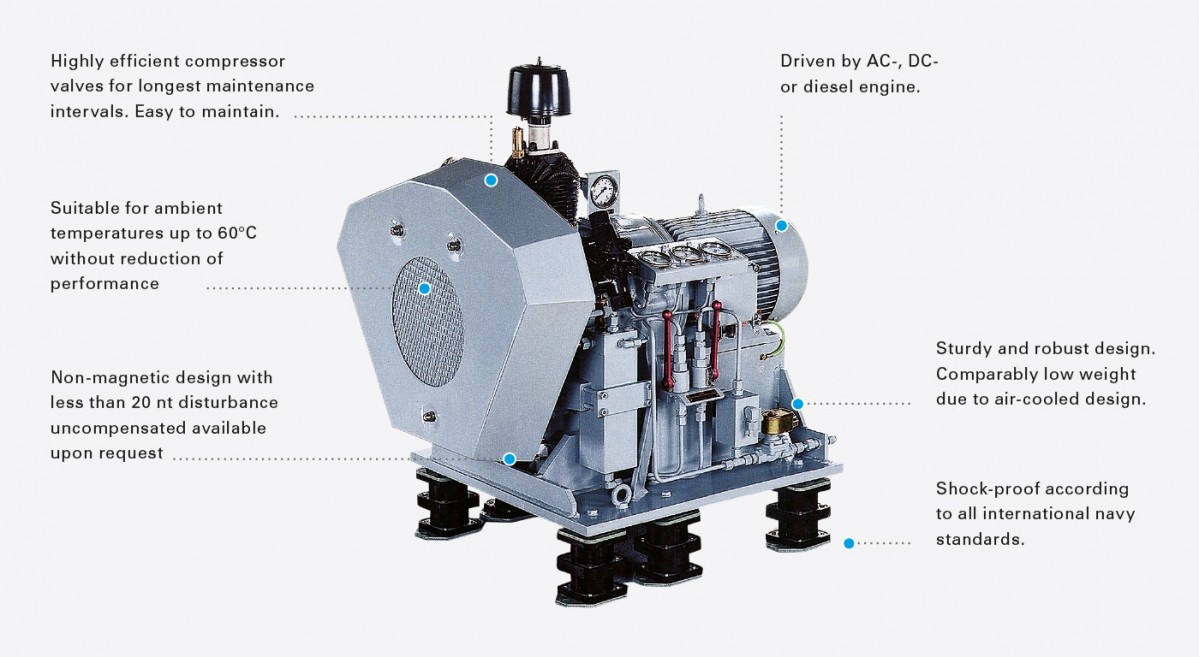

As long ago as 1955, Sauer delivered the first high-pressure compressor to the nascent West German Navy. Since then, many thousand compressors have been delivered to navies all over the world. Specially designed for use on corvettes, frigates, destroyers, mine sweepers, mine hunters, aircraft carriers and submarines, these compressors have worked to the full satisfaction of their naval users. Thanks to our broadly based present-day portfolio we can most certainly supply you with precisely the right high-pressure compressor to meet your specific needs.

Water-cooled compressors series | vertical/in-line type | WP 3230 – 4262

| Type | Stages | Cylinder | Speedrpm | Chargingcapacitym3/h (FAD) | PowerrequiredkW | Weightkg | Lengthmm | Widthmm | Heightmm | FrequencyHz |

|---|---|---|---|---|---|---|---|---|---|---|

| WP 3230–500@ 230 barg | 3 | 2 | 9701,170 | 2530 | 8.010.0 | 650 | 1,400 | 750 | 1,180 | 5060 |

| WP 4253/4254@ 250 barg | 4 | 2 | 750 | 80 | 29.0 | 1,700 | 1,700 | 770 | 1,280 | 50/60 |

| WP 4261/4262@ 250 barg | 4 | 2 | 7501,200 | 80130 | 29.048.0 | 1,7001,800 | 1,7001,750 | 770770 | 1,2801,280 | 50/6050/60 |

| WP 4261/4262@ 350 barg | 4 | 2 | 8001,200 | 80130 | 33.056.0 | 1,7001,800 | 1,7001,750 | 770770 | 1,2801,280 | 50/6050/60 |

Air-cooled compressors | Final pressure 40 barg

| Type | Stages | Cylinder | Speedrpm | Chargingcapacitym3/h | PowerrequiredkW | Weightkg | Lengthmm | Widthmm | Heightmm | FrequencyHz |

|---|---|---|---|---|---|---|---|---|---|---|

| MistralWP 22L | 2 | 2 | 1,1501,4501,750 | 15.920.024.0 | 3.74.65.7 | 120 | 812 | 600 | 630 | 605060 |

| MistralWP 45L | 2 | 2 | 1,1701,4501,750 | 38.048.058.0 | 8.010.012.0 | 310 | 1,210 | 745 | 820 | 605060 |

| MistralWP 65L | 2 | 2 | 1,1701,4501,750 | 52.066.080.0 | 10.212.815.4 | 320 | 1,250 | 745 | 820 | 605060 |

| PassatWP 81L | 3 | 3 | 1,1701,4701,770 | 63.079.096.0 | 13.715.818.9 | 415 | 1,345 | 945 | 900 | 605060 |

Final pressure 250 barg (data for higher pressures upon request)

| Type | Stages | Cylinder | Speedrpm | ChargingCapacitym3/h | PowerrequiredkW | Weightkg | Lengthmm | Widthmm | Heightmm | FrequencyHz |

|---|---|---|---|---|---|---|---|---|---|---|

| WP 3232 | 3 | 3 | 1,1701,470 | 11.014.2 | 5.36.8 | 291 | 920 | 710 | 970 | 6050 |

| HurricaneWP 4331 | 4 | 4 | 1,4701,770 | 30.036.0 | 14.217.2 | 480 | 1,350 | 720 | 930 | 5060 |

| HurricaneWP 4341 | 4 | 4 | 1,4701,770 | 54.065.0 | 20.524.1 | 530 | 1,350 | 860 | 860 | 5060 |

| HurricaneWP 4351 | 4 | 4 | 1,4701,770 | 100.0120.0 | 38.047.0 | 900 | 1,700 | 990 | 1,080 | 5060 |

Non-magnetic technology ideal for use in MCMVs

Compressor of the EK line with three stages in one cylinder – particularly compact and especially suitable for installation in a small vessel.

Water-cooled compressors | vertical single piston | EK type

| Type | Stages | Cylinder | Speedrpm | Chargingcapacitym3/h (FAD) | PowerrequiredkW | Weightkg | Lengthmm | Widthmm | Heightmm | FrequencyHz |

|---|---|---|---|---|---|---|---|---|---|---|

| EK 2 A 2@ 150 barg | 3 | 1 | 870970 | 14.216.2 | 6.17.1 | 370 | 1,150 | 640 | 715 | 6050 |

| EK 2 A 2@ 200 barg | 3 | 1 | 870970 | 1416 | 6.37.3 | 370 | 1,150 | 640 | 715 | 6050 |