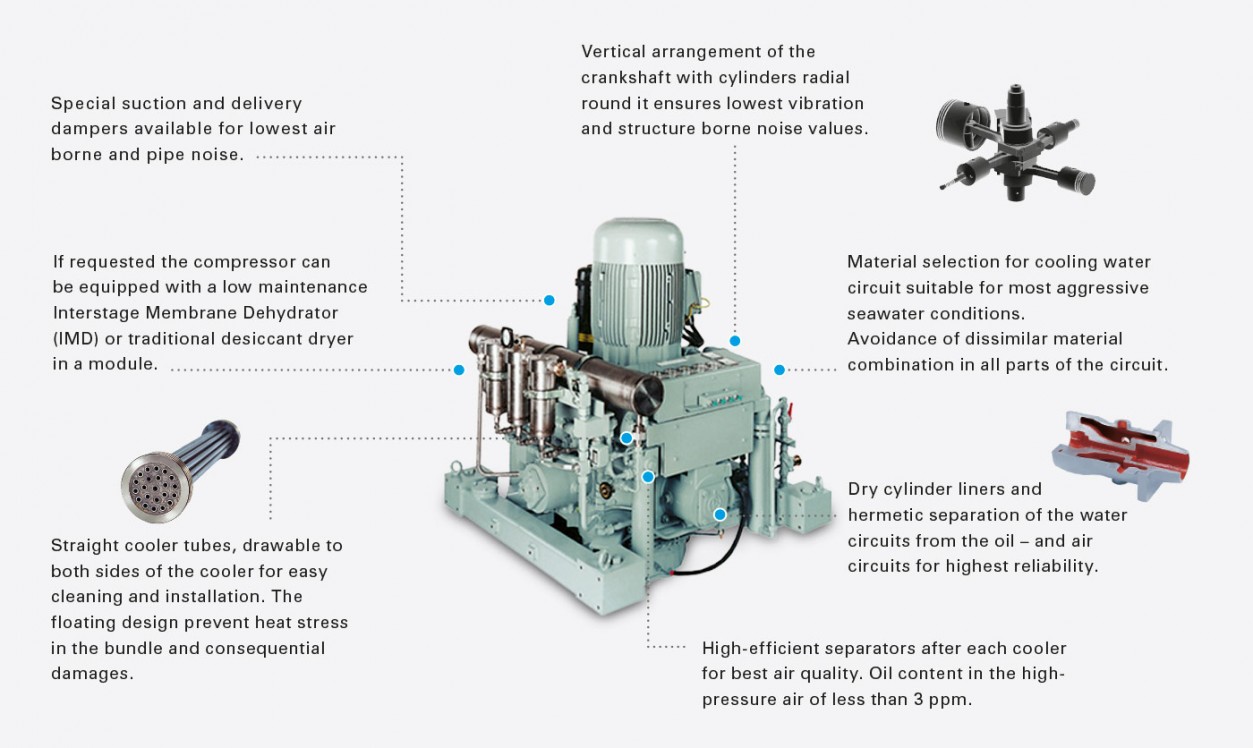

Over 60 years of naval compressor expertise went into the development of the Sauer 5000 series. Like all Sauer compressors, the 5000 series has an outstandingly compact, shockproof design, generates minimal air- and structure-borne noise, features proven technology with first-class worldwide references, and offers state-of-the-art options, such as the latest dryer, control and drive technology. The types WP5000 (200 m³/h@max. 400 bar) and WP5500 (80 m³/h@max. 350 bar) are both vertical-type compressors and can be equipped with either an AC or DC motor. They are suitable for all surface vessels and also available in a highly sophisticated submarine version. The special features of the 5000 series are the vertical crankshaft with the four cylinders radially arranged around it and the directly coupled motor on top of the compressors.

Sauer WP5000 – the naval compressor

Outstanding advantages

As specially designed compressors for use on combat vessels, supply ships or submarines, the 5000 series offers you the specific advantages of future-proof compressor technology, extremely high reliability, as well as the lowest lifetime costs and structure-borne noise emissions on the market.

Fit-for-the-future compressor technology

- Developed in the early 1990s after in-depth analysis of the improvement potential for existing compressors

- Designed with the future in mind, e.g. low maintenance requirements and low structure-borne noise

- Nothing but state-of-the-art technology to minimize the risk of obsolescence in the next 50 years

- Tested and certified to all US Mil, UK NES and German BV standards, for example

Maximum reliability

- CW circuit designed for direct seawater cooling (50 bar) providing high safety margins even when using freshwater

- Dry liners for all compressors stages to avoid internal leakage

- Hermetic separation of oil, water and air spaces

- No internal piping

- Floating cooler stack to avoid heat stress

Lowest lifetime costs

- Valve check/change completed in just 5 minutes

- Withdrawable cooler inserts with straight tubes for easy cleaning

- Compressor embarkable through 800 mm passageway

- No major overhaul required if scheduled maintenance tasks are carried out

- All maintenance tasks performable by on-board personnel

- US Navy contract for carrier fleet with verified cost savings of US$110,000

Lowest structure-borne noise emissions

- Full balancing of free inertial forces and moments thanks to vertical star arrangement of cylinders/pistons

- Dynamic balancing and weight calibration of running gear during production process

- Residual free forces in radial direction easy to attenuate

- Values below mounts in the range of double resilient mounting

Technical Data

Water-cooled compressors | radial / star type | WP 5000/5500

| Type | Stages | Cylinder | Speedrpm | Chargingcapacitym3/h (FAD) | PowerrequiredkW | Weightkg | Lengthmm | Widthmm | Heightmm | FrequencyHz |

|---|---|---|---|---|---|---|---|---|---|---|

| WP 5500@ 250 barg | 4 | 4 | 1,1701,4701,770 | 566882 | 17.221.626.0 | 930 | 970 | 810 | 1,325 | 605060 |

| WP 5000@ 250 barg | 4 | 4 | 1,1701,4701,770 | 115145175 | 34.443.252.0 | 1,650 | 1,215 | 1,095 | 1,570 | 506050 |

| WP 5000@ 400 barg | 4 | 4 | 1,1701,4701,770 | 120150180 | 43.053.062.0 | 1,650 | 1,215 | 1,095 | 1,700 | 506050 |