![]()

Hydrogen Compressors

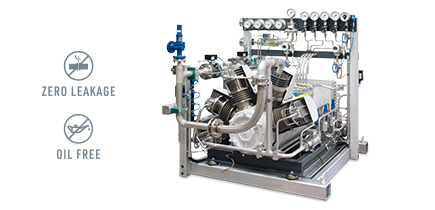

Compressors from the HAUG product line stand out by their oil-free and hermetically gas-tight design.

HAUG hydrogen compressors are based on more than 30 years of experience. The first HAUG hydrogen compressor was already used in 1989 in a solar power demonstration project in Germany. As the compressors are completely dry-running and oil-free, there is no danger of oil-vapour contamination of hydrogen and the equipment downstream. Due to the unique combination of high-pressure cylinders with NanoLoc® design, the HAUG.Mercure NanoLoc and HAUG.Sirius NanoLoc series can reach final pressures up to 450 barg. The compressors are particularly compact and can be operated very efficiently thanks to a variable intake pressure.

✓ Oil-free and dry-running design

✓ Hermetically gas-tight

✓ NanoLoc® high-pressure stages

✓ Inlet pressures of up to 30 barg

✓ Suitable for final pressures up to 450 barg and max. volume flow rate of up to 100 m³/h

✓ Ex-proof versions acc. to ISO 80079-34:2020 and the European ATEX directive 2014/34/EU

![]()

■ Hermetically gas-tight with encapsulated electric motor

| Type | Gas Inlet Pressurebarg | Gas Outlet Pressurebarg | Flow Ratem³/h | Rated PowerkW |

|---|---|---|---|---|

| HAUG.Mercure NanoLoc 22E 25-13 LM-L | 24 | 350 | 7 – 13 | 4 – 5.5 |

![]()

■ Hermetically gas-tight with magnetic coupling

| Type | Gas Inlet Pressurebarg | Gas Outlet Pressurebarg | Flow Ratem³/h | Rated PowerkW |

|---|---|---|---|---|

| HAUG.Sirius NanoLoc 22G 25-13 LM-L | 24 | 350 | 14 – 24 | 9 – 15 |

| HAUG.Sirius NanoLoc 42G 25-13 LM-L | 24 | 350 | 28 – 48 | 18 – 30 |

| HAUG.Sirius NanoLoc 42G 35-16 LM-L | 29 | 270 | 100 | 25 |

![]()

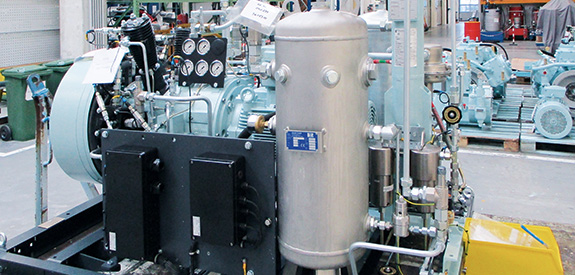

The product line SAUER stands for oil-lubricated heavy-duty machines that are an efficient and economical solution for all kinds of industrial hydrogen applications.

✓ Special gas-tight design

✓ Proven in the most demanding conditions in industry and offshore applications

✓ Inlet pressures of up to 20 barg

✓ Suitable for final pressures up to 350 barg and a max. volume flow rate of up to 1,000 m³/h

✓ Ex-proof versions acc. to ISO 80079-34:2020 and the European ATEX directive 2014/34/EU

The 4-stage air-cooled high-pressure compressors of the Hurricane series are the top choice for demanding applications.

■ 4-stage compression

■ Direct drive

■ High-efficiency air cooling

| Type | Gas Inlet Pressurebarg | Gas Outlet Pressurebarg | Flow Ratem³/h | Rated PowerkW |

|---|---|---|---|---|

| WP4331 BasSealH2 | 0.05 | 350 | up to 26 | 15 |

| WP4341 BasSealH2 | 0.05 – 0.2 | 350 | up tp 36 | 22 |

| WP4351 BasSealH2 | 0.05 – 0.2 | 300 | up to 76 | 38 |

The water-cooled compressors of the SAUER 6000 series have a modular design with up to six cylinders, which allows many different variations. As the largest piston compressors of their kind, they allow maximum performance even in the most difficult conditions.

■ Modular 4 or 6 cylinder design

■ Up to 5-stage compression

■ Hermetically gas-tight magnetic coupling drive

■ Water-cooling system with individual cylinder/inter-stage cooling

| Type | Gas Inlet Pressurebarg | Gas Outlet Pressurebarg | Flow Ratem³/h | Rated PowerkW |

|---|---|---|---|---|

| 6000 series BasSealH2 | 0.05 – 20 | 350 | up to 1,000 | 132 – 230 |