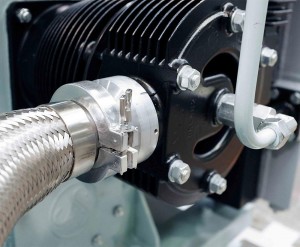

For more than 50 years Sauer Compressors specialises in the development and production of gas-tight helium compressors. Our comprehensive experience is incorporated in every product and new development – for the benefit of the customer.

Sauer helium compressors are specially designed for helium compression and represent the most efficient and safe solution for all kinds of applications. So it is no surprise that leading research institutes and universities only trust in Sauer helium compressors.

Gas companies profit from the unique advantages of Sauer helium compressors and the support of the worldwide sales and service network of the Sauer Compressors Group.