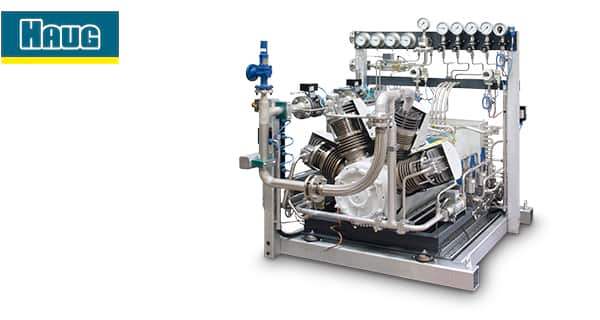

Dependable up to 500 bar –

Simply dependable – Reliability and quality have been our guiding principles for over 140 years. Our customers know they can trust us to deliver. These principles guide us in the development and manufacturing of state-of-the-art high-pressure compressors, in our comprehensive service offering, and in staying customer-centric.

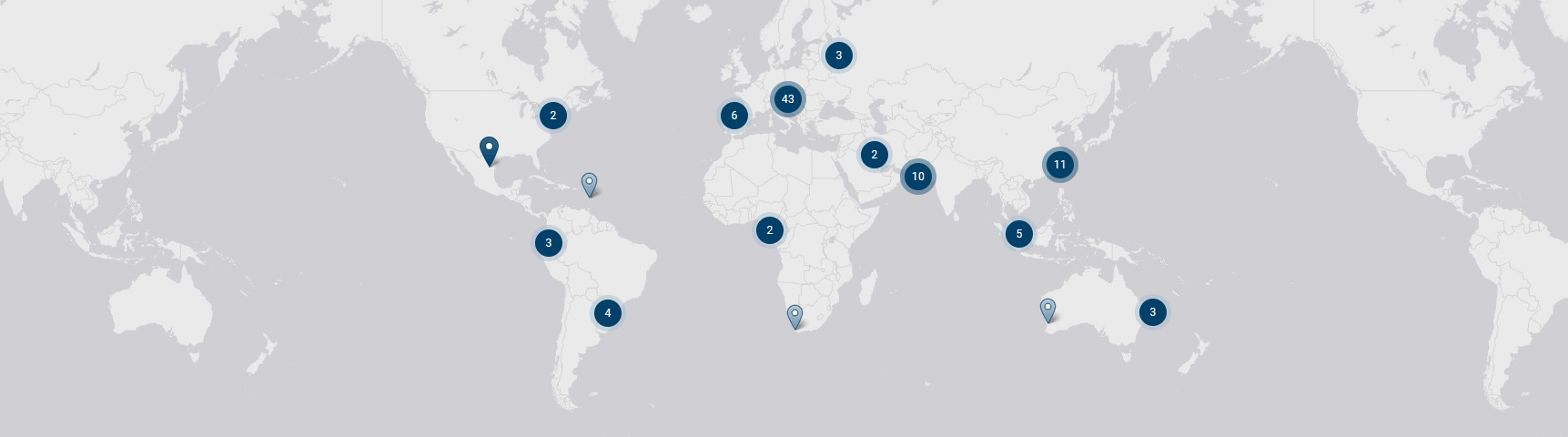

As one of the leading vendors in the industry, offshore, commercial shipping and the defence sector, you will find us all over the world – and ready to serve you with reliable, high-quality products and services.

Applications

Industry

Find the industry applications hereCommercial Shipping

Read about commercial shipping applications hereOffshore

More on Offshore applicationsNews | 2024

Sauer Compressors with two new managing directors

Two new managing directors strengthen the management team of the Sauer Compressors Group. The compressor manufacturer has appointed Nicole Fässler as CFO and Mladen Milcinovic as COO as of 1 January 2024.

Read more here All news

News | 2024

Sauer Compressors acquires Swedish sales partner

Sauer Compressors is proud to announce the acquisition of Söders Maskinservice to establish a scandinavian subsidiary.

Get the press release here All newsPartners around the world

Use our search to find your point of contact.